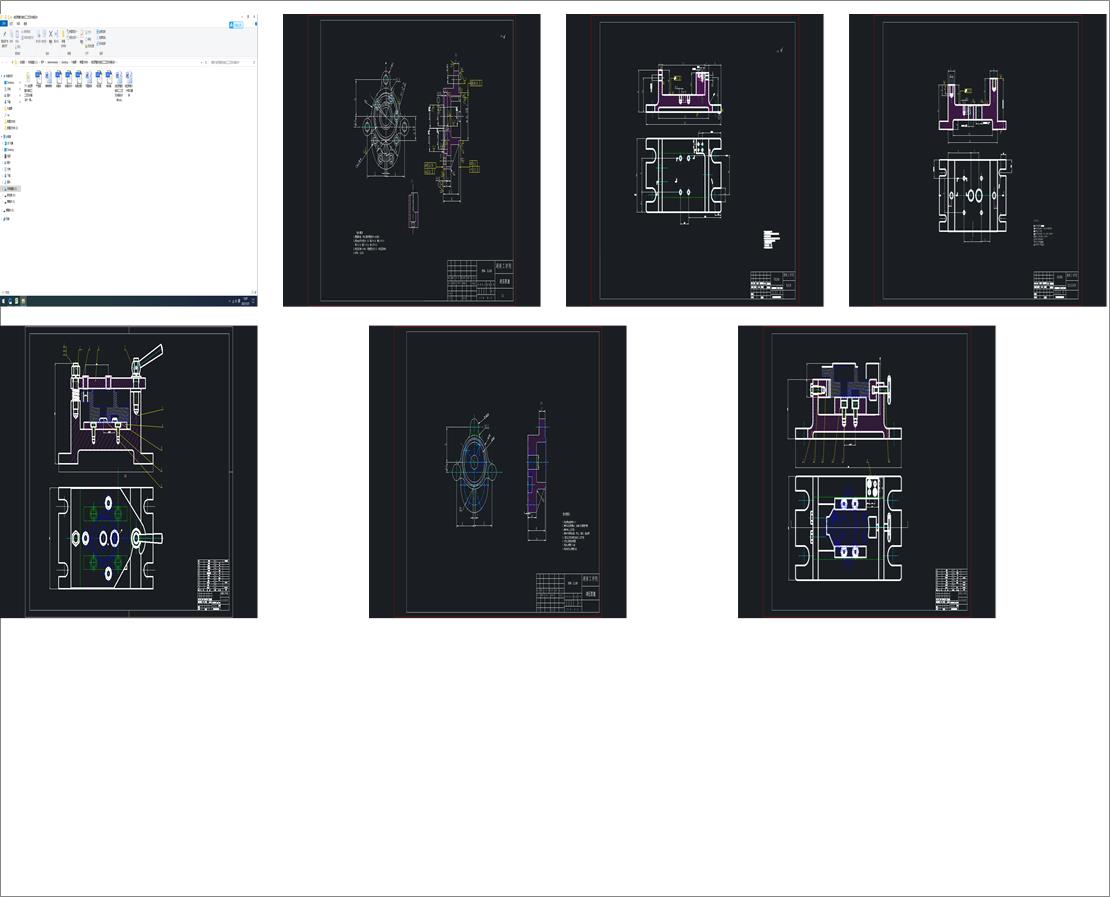

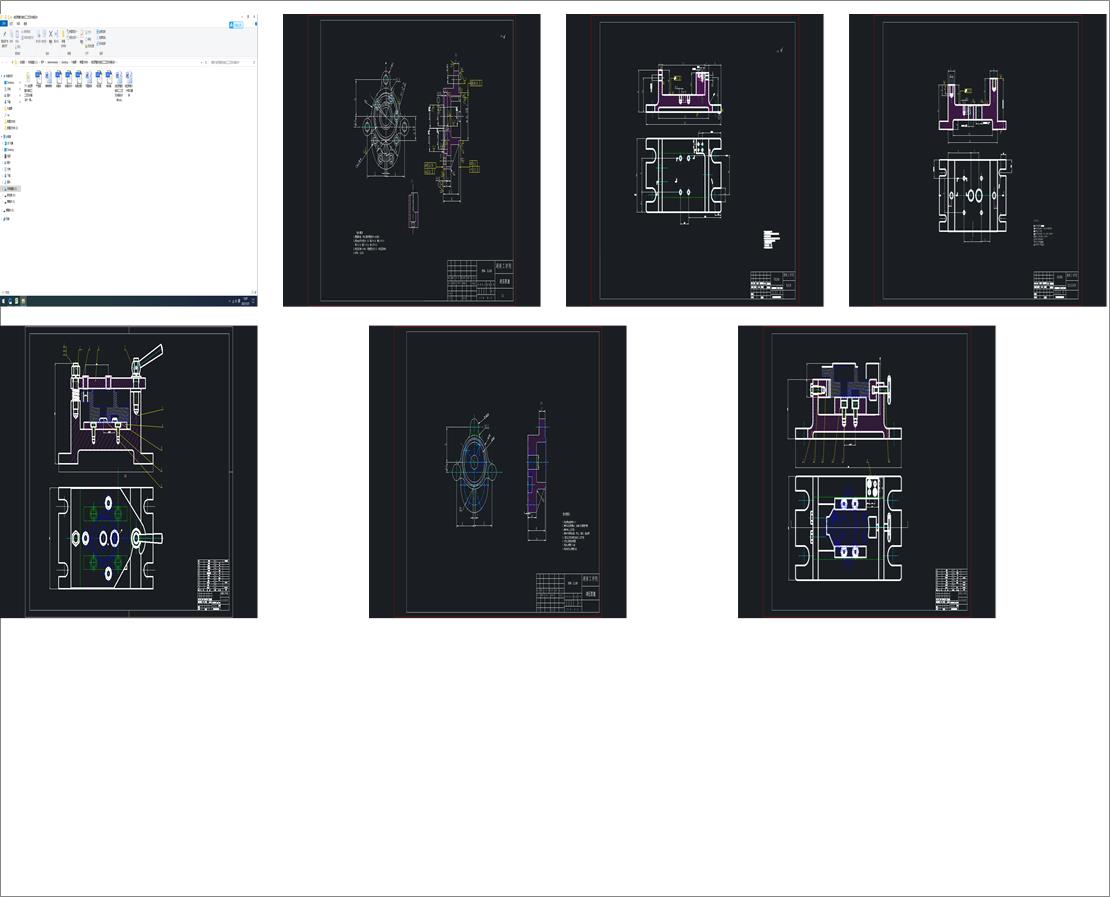

油壓泵蓋機械加工工藝及夾具設(shè)計

- 文件介紹:

- 該文件為 rar 格式��,下載需要 20 積分

-

- 油壓泵蓋機械加工工藝及夾具設(shè)計摘 要

泵是一種重要零件��,被廣泛的使用��,例如汽油泵��,液壓泵�����,潛水泵�,隔膜泵等產(chǎn)品��,它在機械行業(yè)中的作用是不能被隨便取代的����,本課題選的是泵蓋的機械加工工藝及夾具設(shè)計,因為泵蓋是和泵密切相關(guān)的零件����,在設(shè)計過程中�����,從大量的有關(guān)書籍中綜合比較與選擇最好的設(shè)計方案��。液壓泵蓋零件重要是目前機械行業(yè)中不可否認的事實�,采用傳統(tǒng)的工藝����,如鉆,擴����,銑等,不僅效率低且穩(wěn)定性差��,精度不容易保證�,約束著生產(chǎn)的發(fā)展,對于大批量生產(chǎn)的零件應(yīng)采用組合機床進行加工�,不僅快捷高效而且生產(chǎn)率高,是機械加工的最佳發(fā)展方向�����。由課題給定的設(shè)計題目可知�����,應(yīng)采取什么樣的措施來解決泵蓋加工設(shè)計及夾具設(shè)計的過程中所存在的主要問題。如毛坯制造形式獲得的具體確定��,基準(zhǔn)面的選擇��,工序尺寸及空白�����,工藝路線的確定�,切削用量的確定。在專用夾具設(shè)計的過程中存在著許多值得注意的問題�����,設(shè)計出準(zhǔn)確合理的夾具是保證零件合格的重要條件�����,夾具設(shè)計中操作說明書亦很重要��。此次設(shè)計能夠完成主要感謝我的老師及同學(xué)們的大力支持與幫助����,向他們表示衷心的感謝。

關(guān)鍵詞 :工藝��;夾具設(shè)計

ABSTRACT

Pump is a kind of important parts, is widely used, such as gasoline pump, hydraulic pump, submersible pump, diaphragm pump and other products, its role in mechanical industry can't be replaced by random, this topic is optional pump cover mechanical processing technology and fixture design, because the pump cover are closely related and pump parts, in the design process, from a large number of relevant books comprehensive compare and choose the best design solution. Hydraulic pump cover is one of the important parts in the machinery industry there is no denying the fact that adopts the traditional process, such as drilling, expanding, and milling, etc., not only low efficiency and poor stability, not easy to ensure accuracy, constrains the development of production, should be used for mass production parts modular machine tool for processing, not only efficient but also the productivity is high, is the best development direction of mechanical processing. Designed by the topic of a given topic, what measures should be taken to solve the pump cover processing design, fixture design and the main problems existing in the process of. Such as blank making form of concrete, the selection of the datum, the process and blank size, the determination of process route, cutting parameter determination. In the process of special fixture design, there are many noticeable problems in design of fixture is accurate and reasonable guarantee the important conditions of qualified parts, fixture design in the operating instructions is also very important. This design can be completed mainly thanks to my teacher and classmates support and help, to express our heartfelt thanks to them.

Key words: process; Fixture design.

目 錄

前言 4

一. 零件的分析 5

1�、零件的作用 5

2、零件的工藝分析 6

二����、零件工藝規(guī)程設(shè)計 7

1. 確定毛坯的制造形式 7

2. 基準(zhǔn)面的選擇 7

3. 制定工藝路線 8

4. 機械加工余量、工序尺寸及毛坯尺寸的確定 10

5. 確定切削用量 11

6. 小結(jié) 21

三 專用夾具設(shè)計 22

1. 問題的提出 22

2. 粗�����、精銑零件上平面夾具設(shè)計 22

3. 定位基準(zhǔn)的選擇 22

4. 銑削力與夾緊力計算 22

5. 夾具設(shè)計及操作的簡要說明 25

6. 鉆3-φ11孔夾具設(shè)計 26

6.1 定位基準(zhǔn)的選擇 26

6.2定位元件的設(shè)計 26

6.3定位誤差分析 26

6.4鉆削力與夾緊力的計算 27

6.5襯套��、鉆模板及夾具體設(shè)計 27

6.6夾緊裝置的設(shè)計 28

6.7夾具設(shè)計及操作的簡要說明 28

7. 小結(jié) 30

參考文獻 31

致謝 32

...